4th Consistent Award Winning Year!

Design Your Dream Space with Us Today!

Expert For HOME COMPLEX OFFICE HOSPITAL SHOWROOM

Transform Your Vision into Reality: From Concept to Construction, Our Architects Bring Your Dreams to Life. Let’s Build Something Beautiful Together!

Architect & Interior Design Doesn't Have to Be Expensive or Complicated! It Should Be Smart & User Friendly

Ar, Pankaj Chiraniya, Founder Of Chiraniya Consultancy & Building Caretakers

Established

Architect Interior Design Company Based in Akola, Maharashtra

We deliver exceptional design and construction services to bring our clients’ unique visions to life. Our experienced architects and interior designers work closely with clients to create innovative and creative design solutions while maintaining clear communication throughout the process.

Our goal is to provide a seamless, stress-free experience and deliver the highest quality results on time and in budget. Trust us to build your dream home or transform your existing space into something beautiful. Contact us today to get started!

Ar. Pankaj Chiraniya, Founder

Vastu

Unlock the Power of Harmony with Vastu

3D Design

Transforming spaces with precision and depth

Visualization

Design with confidence, backed by expert visualization

Own Material Choice

Transform your space with the perfect material match

Customer Support

Exceptional Customer Support from our Interior Design Team

Our Recent

Award Winning Projects

Chiraniya Consultancy was honored to work on Akola’s Paldiwal interior civilian design project. Our talented team created functional and stylish spaces while working closely with the Akola team to align with their vision, goals, and budget.

We managed every aspect of the process, delivering high-quality results that exceeded expectations. Contact us to bring your vision to life

- Awarded Best Architect Vidarbha Maharashtra - 2022

- Udyogak Award - 2022

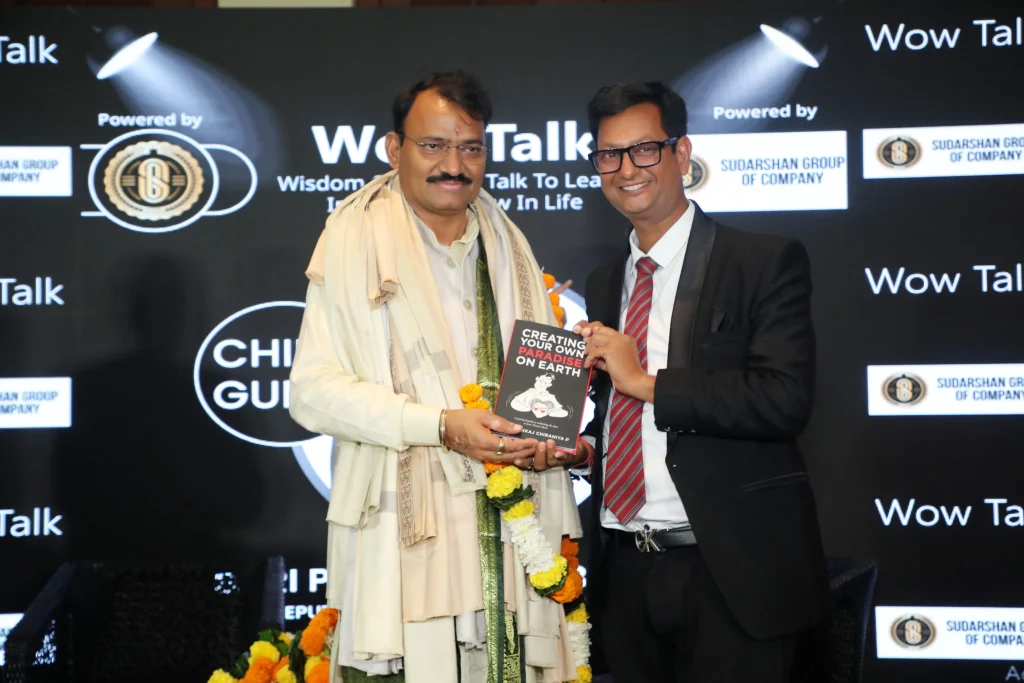

- Wow talk star speaker Award -2024

- Business Icon Award - 2024

Every Space Count

Why Choose Us

Building Planning

Transform your space with precision and style through our expert building planning services.

Renovating Space

Revitalize your space with our expert renovation services and transform it into your dream design.

Interior Space

Elevate your interior space with our innovative and stylish design solutions.

Project Management

Relax and watch your dream space come to life with our expert project management Manager.

Valuations

Unlock the true potential of your space with our accurate and reliable valuation services.

Free Consultation

Transform your space with our expert design guidance - book your free consultation today!

Succeeding Project

Services We Offer

Architectural Designing

Book Your Free Consultation

Click NowInterior Designing

Book Your Free Consultation

Click NowLandscape Designing

Book Your Free Consultation

Click NowLayout Designing

Book Your Free Consultation

Click NowR.C.C. Designing

Book Your Free Consultation

Click NowProject Management Consultancy

Book Your Free Consultation

Click NowRenovation

Book Your Free Consultation

Click NowEnergy Efficient Architecture

Book Your Free Consultation

Click NowTestimonials

What Our Clients Say

From concept to reality, our architecture service delivers exceptional design solutions.

Awarded By

Pankaj Chiraniya is an extremely talented and well-recognised architect designer based in Akola, Maharashtra. His firm, Chiraniya Consultancy, has been providing quality services for many years, earning him an outstanding reputation. Recently, Pankaj was awarded the title of Best Architect in Vidarbha Region of Maharashtra, showcasing his excellence in the field. Pankaj’s designs have always been lauded for their creativity and attention to detail, and this award will only serve to further prove his worth in the industry.

Best Ranked By

Are you stuck with small space design ideas?

Are you struggling with small space design ideas? Don’t worry; you’re not alone. Designing small spaces can be quite a puzzle.

Transforming your space with creative Shelves decoration ideas

Have you ever wondered how a simple piece of furniture could hold the power to transform an entire room? Imagine this:

Puja room design ideas for your home

Perfect Puja room design ideas for your home; Ideas and inspiration In a Hindu household, the puja room holds a position